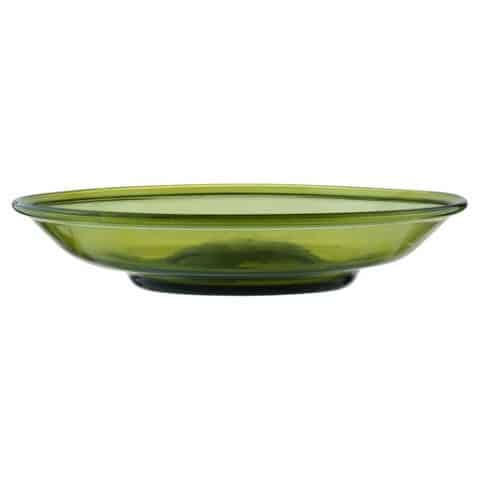

Kent Pattern Molded Bowl

Kent Pattern Molded Bowl

20 SwirlED Ribs

Franklin Glass Works, Portage County, Ohio

Pale Yellow-Green Bowl

Provenance: John Fifer Collection, ex Darl Fifer Collection

Within the museum third floor Free Blown & Pattern Molded Gallery, there is the Tableware Room. In one segment of the large room, you will see the Ohio glass displays for Kent, Mantua, Ravenna, and Zanesville which played an important part in glassmaking history in the United States. One section is reserved for Franklin Glass Works in Portage County, Ohio where our subject Kent pale-green bowl was made somewhere between 1824 and 1830.

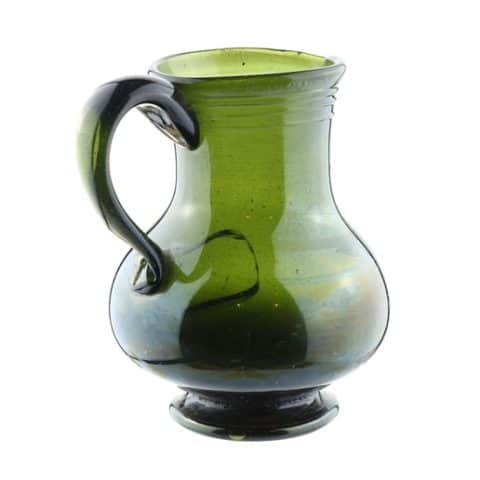

For many years before and after its excavation, the glasshouse has been called the Franklin or the Kent Glass Works, terms used nearly interchangeably by researchers and collectors of Midwestern American glass. While in operation, the glassworks produced several distinctive patterns of glass flasks and decanters blown into two-piece and three-piece molds, and much free-blown pattern molded decorated tableware.

See the museum example of a Kent Blown Three Mold Decanter.

Pattern molded is glassware that has been blown into a mold whose interior has a raised pattern so that the object shows the pattern with a concavity on the inside, underlying the convexity on the outside. Pattern molds are not used to impart the final form to the object.

Our subject Kent Pattern Molded Bowl measures 7-½” wide by 2-½” tall. The bottom measures 3-¾ diameter in circumference and has a pontil mark. The pale yellow-green bowl is defined with 20 swirled ribs.

FRANKLIN GLASS WORKS

The site of the Franklin Glass Works was first discovered in 1928 by 1985 FOHBC Hall of Fame recipient Harry Hall White. Mr. White, from Cleveland, Ohio, discussed Kent Glass Works in his papers and published his discoveries in Antiques Magazine in 1934 and 1935. Included in his research was a picture of a field with a barn with two gables in the background.

In 1964, Bordon Company executive Duncan B. Wolcott studied White’s papers and started knocking on doors in the area looking for the old glassworks. In 1966, he was joined by Cleveland lawyer James E. Courtney. Wolcott eventually found a barn that closely matched White’s picture. He drove up the driveway to the house on the property and was greeted by Dale E. Hissem. When asked if he ever heard of an old glass factory on his land he said, “It’s back in my cornfield. Every spring when I plow, I turn up hundreds of glass fragments and bricks.” Wolcott followed Hissem to the spot which was “about a half-mile from Seasons Road.” The ground was strewn with broken pieces of glass, bricks, and pieces of broken clay pots.

Wolcott and Courtney obtained a substantial grant from the Kettering Family Foundation to bring scientists to explore the ruins in the late 1960s. The archaeologists worked with tools such as whisk brooms, small paintbrushes, trowels, and screens to dig 18 to 24-inch holes and sometimes deeper. They initially found bits of glass, hardware, pewter buttons, and Indian arrowheads.

Ultimately the excavation revealed several ovens plus the main furnace. Most of the glassware made at the Franklin Glass Works were bottles, flasks, tumblers, and milk pans patterned in dip molds, having a plain or swirled rib design like our subject bowl. After the glass was melted in the furnace, it was blown into molds to form bottles, jars, dishes, decanters, flasks, pitchers, pans, bowls, vases, tumblers, scent bottles, and ink bottles. These products were tempered in the cooling ovens in which eight were found on the site.

Five colors of glass were found in abundance on the site – aquamarine, light amber, deep reddish amber, yellow-green, and olive green. Many of the shards were primitive and the colors were not always uniform. The excavation also turned up square nails, charred wood, sandstone, and hundreds of pieces of blue English china which was probably used by the workmen for their meals at the factory.

It is believed that the Franklin Glass Works factory was established in 1823 at a site that was near to all the necessities of glassmaking. Sand or sandstone was there to be melted and mixed with potash and limestone to make glass. A kiln was nearby where bricks for the ovens were made. Clay was available to make the crucibles needed to hold the molten glass and there were plenty of trees to provide wood to fire the furnaces.

A major industrial accident in the winter of 1830/31 caused the glasshouse to cease operations and close.

Primary Image: Kent Pattern Molded Bowl (pale yellow-green), Kent Pattern Molded 20-Rib Chestnut Flask (pale yellow), Kent Pattern Molded Bowl 20-Ribs Left (green aquamarine), and Kent Blown Three Mold Decanter (aquamarine) imaged by the FOHBC Virtual Museum midwest studio by Alan DeMaison.

Support Image: Blown pattern-molded lead-glass bowl, 1800–1830, Made in Ohio, H. 2 15/16 in.; Diam. 9 1/8 in., Rogers Fund, 1939 – Metropolitan Museum of Art

Support: Reference to The Franklin Glassworks – The Archaeology of an Early Nineteenth-Century Ohio Industry by David S. Brose with contributions by George Miller, David Frayer, Donna Benson, Melissa Arnold, Dean Zimmerman, and Alfred Lee. Archival Report to the Ohio History Center, Columbus, Ohio. David S. Brose, 2020

Support Image: Extremely rare, Kent Ohio Glass Works pattern molded bowl, with 20 swirled ribs, in a beautiful topaz yellow-amber color. There is a near-identical example in the Metropolitan Museum NYC, however, this example has a better impression and color with more yellow highlights! – John De Caro, Glass International LLC

Support Image: Vase. Transparent light green glass with black impurities; wear marks at base; blown-three-mold; body tapering to slightly concave base with pontil mark, sharp contraction at top to form a wide collar-like bulge, wide flaring rim; patterned in pint decanter mold in pattern G II-6. Probably Kent, Ohio, 55.4.231, Overall H: 13.8 cm; Rim Diam: 9.7 cm; Base Diam: 6 cm, about 1824-1830 – Corning Museum of Glass

Support Image: Decanter. Bottle glass, bubbly, light yellowish olive-green; blown-molded for pattern; large squat ovoid body, long plain tapering neck with round-collared small mouth; geometric pattern (GII-6): band of vertical ribs between bands of diamond diapering, gadroon ribbing at top, wide single horizontal rib between bands, plain base; rough pontil mark. Park, Edmonds & Park, Manufacturer, possibly Kent, Ohio, 50.4.134, Overall H: 21.3 cm, Diam (max): 14.3 cm, about 1823 – 1830 – Corning Museum of Glass

Support: Reference to American Bottles and Flasks and Their Ancestry by Helen McKearin and Kenneth M. Wilson, Crown Publishers Inc., New York, 1978.

Support: Reference to Archaeology In a Portage County Cornfield by Charles Buffum, Akron Beacon Journal, November 30, 1869.

Support: Reference to Ohio Glass 1815-1953, The Toledo Museum of Art, October 1953

Support: Reference to History of the Franklin Glass Works, Portage County, Ohio By George L. Miller, Summer 2004, Bottles and Extras

Join the FOHBC: The Virtual Museum is a project of the Federation of Historical Bottle Collectors (FOHBC). To become a member.